OUR PROCESS

Miniati Lab is a company that combines skills, expertise, experience and professionalism, where the bond with tradition and craftsmanship lies in our approach, which does not involve a standard industrialized process, but rather follows every project from the idea to its final completion and performance tests, to guarantee the utmost custom-made quality: unique products, with care for every detail, designed to last through time.

Conceived, designed and created around the client. Quality and beauty meet uniqueness.

TECHNICAL ASSISTANCE [PRELIMINARY]

Preliminary analysis of the outline design with the client

Feasibility study:

- Analysis and choice of materials

- Analysis and choice of processing and finishes

- Purchasing strategy

- Consideration of possible logistics problems (transport and assembly of completed work)

- Time planning with expected schedules for the various phases of the project

Indication of technical solutions for designer’s working drawings

Cost estimates and preliminary budget

Economic feasibility study and payment solutions.

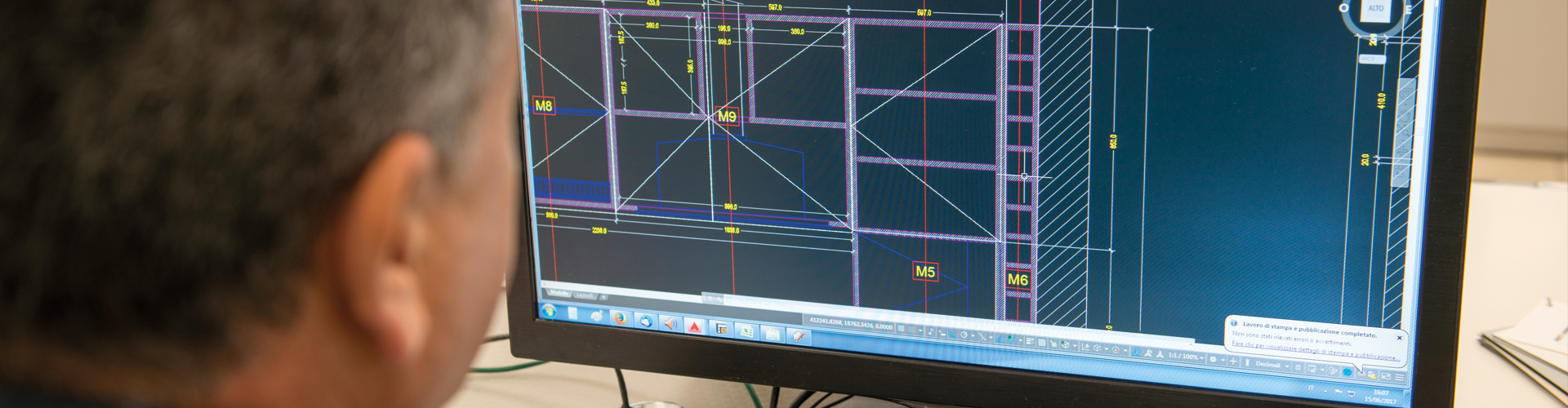

DESIGN PROCESS [CAD/CAM]

Analysis and preliminary assessment with client’s designer

Resolving problems and technical choices for the project

Technical site inspection

Technical survey for project design (with laser/photometric equipment). Transposition into CAD/CAM language

Project design and engineering of structural elements

Final working drawings produced for approval by pre-production designer

CAD/CAM design with 3/5 axis CNC machining centre programmes

Three dimensional modelling and rendering.

PROJECT MANAGEMENT

Coordination of project process

Timing/quality management and control

Coordination of suppliers and special processes

Monitoring of purchasing and delivery logistics

Supplying the documentation for site safety and procedures

Coordination of site activities until final testing.

CUSTOM MADE

SUPPLY AND PRODUCTION

Working designs based on technical survey

Production of custom made furniture

Production of complex elements (coordination and assembly of processed parts and products from external suppliers)

Processing with 3/5 axis CNC machining centres, membrane for producing curved parts, panel saw, hot presses

Internal lacquering machine

Research and development centre: innovative materials, assembly systems, processing techniques

Transport, assembly with specialised internal personnel.

TURNKEY SERVICE

Management and coordination of the complete project

Supply and installation of the finished commercial products

Supply and installation of the upholstery

Site management until final inspection

Light construction work

Mechanical, electrical, plumbing and air conditioning systems

Metal and glass products.

POST SALES SUPPORT

Final testing and detailed inspection of post-installation products

Condition inspection (satisfactory/unsatisfactory) of all the elements that complete the product

Reinstatement operations and post-installation technical modifications

Technical consultancy (from design to construction) for rapid solution of new requirements from the client

Information on company initiatives of interest to the client

Tailormade services for ordinary and/or extraordinary maintenance.